WASTEWATER TREATMENT SYSTEMS

The following lists some historical project examples of the wastewater systems completed

- Operations Camp Package Wastewater (Sewage) System

- School Wastewater System

- Industrial Wastewater System

- Process Wastewater Recyle System

- Other P&IDs

1. 2 x 20,300 USGPD (or 2 x 76,900 L/day) Construction + Operations Camp Package Wastewater Treatment Systems – Northern Alberta SAGD Site – currently being editted

Each advanced package sewage system discharges via an effluent dosing pump station to an at-grade absorption disposal area – utilizing 100 x 20 m pressurized laterals covered with a perforated chamber and wood chips. Package Sewage System process steps includes lift stations, fine screens, equalization, aerobic membrane bioreactor system, UV disinfection system, treated effluent holding tank, effluent dosing pump station, and an at-grade disposal system. The accumulated sludge was handled by an aerated sludge holding and decant thickening system with thickened sludge periodically removed to an approved regional/municipal sewage plant. Each packaged system was placed within a custom modular building to service a camp population of 500. Basis for each system were 2 x 350 man off-the-shelf modular package sewage systems to handle camp population fluctuations that varied from 100 to 500 people. The systems was designed to be moved by flatbed truck and can be used to treat sewage/wastewater from a construction, work, and/or operations camps. Plan to use 2 x 350 Man System at a 500+ man SAGD Construction Camp and then move one or more of the 350 Man Systems to future SAGD Construction Camps. The Operations Camp in the future would get a new 125 Man System but for the time being would use one of the 350 Man Systems until such time that the future SAGD Construction Camps were ready.

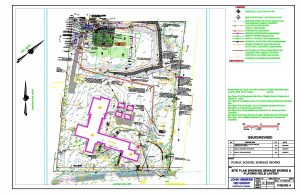

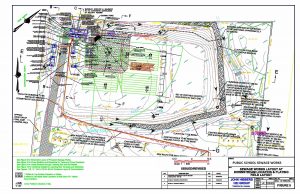

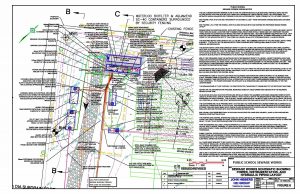

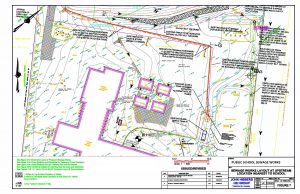

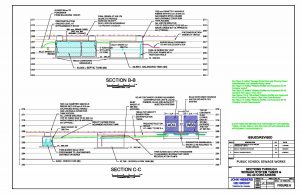

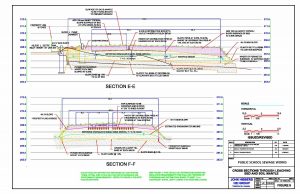

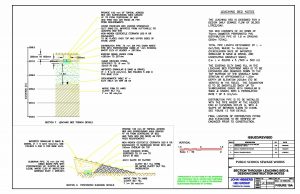

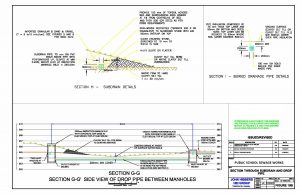

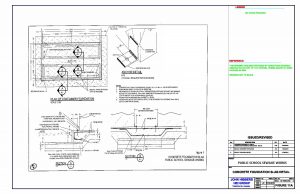

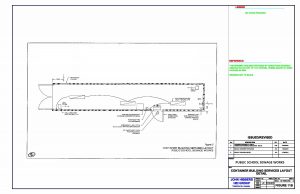

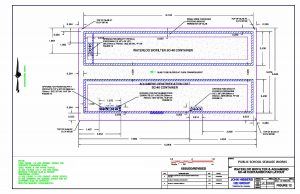

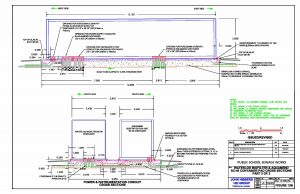

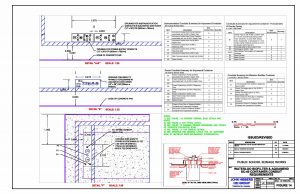

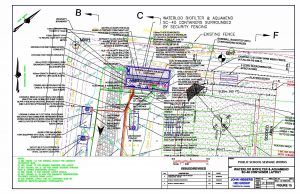

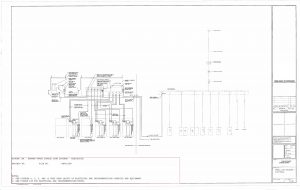

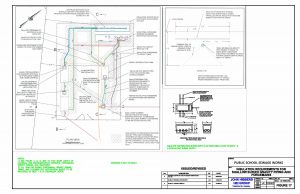

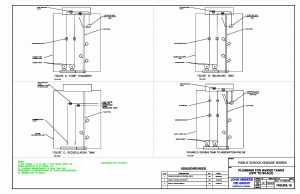

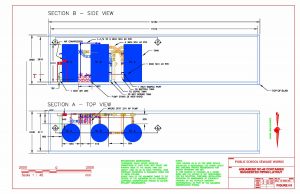

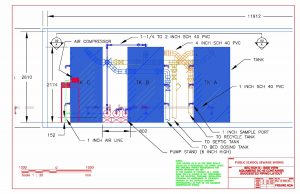

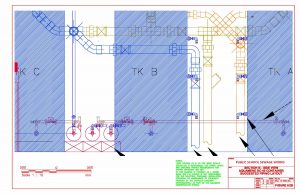

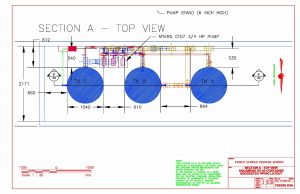

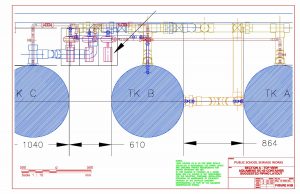

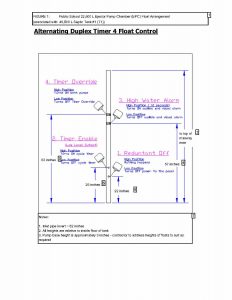

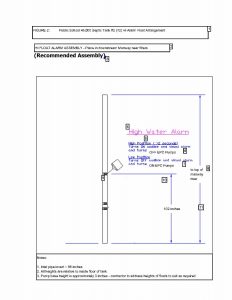

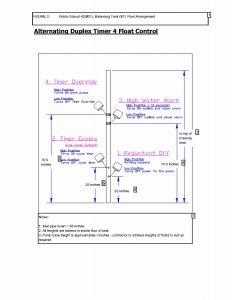

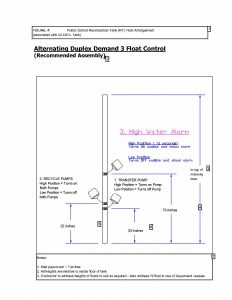

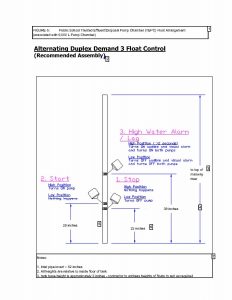

2. 30,000 L/day School Wastewater System

The package sewage system met the requirements for a Class 4 septic system (reference Part 8 of the Ontario Building Code, 2006). The Package Sewage System process steps included lift stations, floating solids removal, equalization, dosing tank and pump system to trickling filter, trickling filter bioreactor type system, biological nitrogen and phosphorus reduction, treated effluent holding tank, effluent dosing pump system, subsurface absorption disposal field.

Return to top

3. Industrial Wastewater System

Return to top

4. Process Wastewater Recyle System

Return to top

5. Other P&IDs

[Important Notes! – More drawings to be added in future]