UPSTREAM HEAVY OIL FACILITIES

The following lists some historical project examples of the heavy oil facilities completed

- Cold Heavy Oil Production with Sand (CHOPS) Facilities

- Produced Water Disposal System

- Single Well Test Equipment Setup

- Other P&IDs

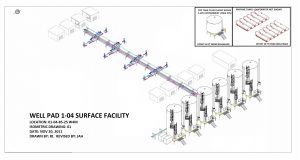

1. Cold Heavy Oil Production with Sand (CHOPS) Facilities – 300 bbl/day per Well Pad Facility in Northern Alberta

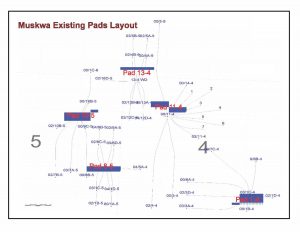

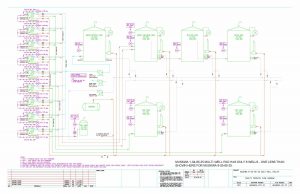

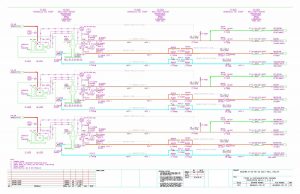

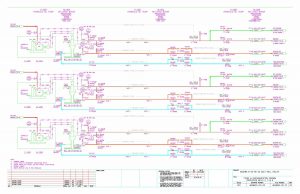

Well Pad Facility 1-04 is the third of five constructed well pad facilities. All the major equipment for the 1-04 Pad Facility are located within the lease boundary that forms part of location 1‐04‐85‐25 W4M. This is a cold conventional heavy oil pad that was completed in June 2011. This project achieved the objective of constructing an 8 well crude bitumen production facility. The produced water, oil and sands are separated in stock tanks. The produced oil is trucked for sale and the produced water and sands are trucked out to a third party waste processing facility or disposed of via the 13‐04 Pad water disposal well. Even though this was the best oil production well pad the profile did not perform as would be expected from true CHOPS wells. The capital cost for this pad was approximately, $9.1M (includes pad/road construction, drilling, completions, surface facility, engineering, geology, and head office overhead)

Well Pad Facility 8-05 is the fourth of five well pad facilities. All the major equipment and the are located within the lease boundary that forms part of location 8‐05‐85‐25 W4M. This is a cold conventional heavy oil pad that was completed in December 2011. This project achieved the objective of constructing a 9 well sweet crude bitumen production facility. The produced water, oil and sands are separated in stock tanks. The produced oil is trucked for sale and the produced water and sands are trucked out to a third party waste processing facility or disposed of via the 13‐04 Pad water disposal well. This pad was a relatively poor oil production pad compared to the 1-04 Pad. The capital cost for this pad was approximately, $9.6M (includes pad/road construction, drilling, completions, surface facility, engineering, geology, and head office overhead)

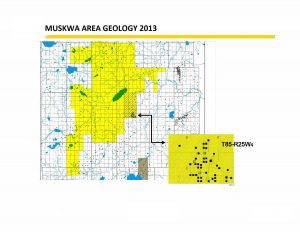

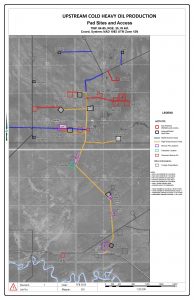

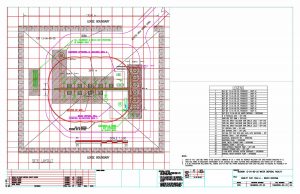

Muskwa Development Area – Locations of Wells and Surface Facilities:

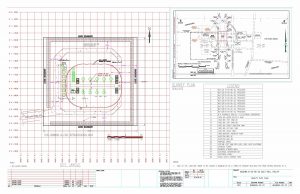

Plot Plan and Isometric Drawings:

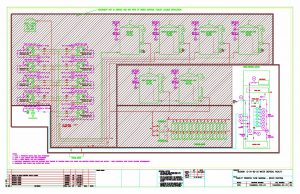

PFD Drawing:

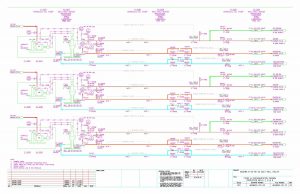

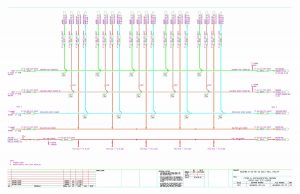

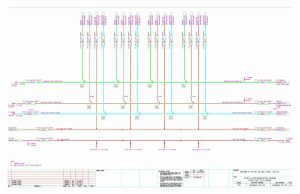

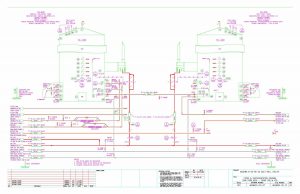

PID Drawings:

Return to top

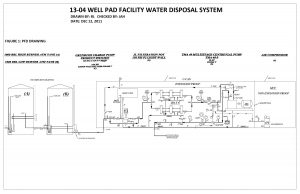

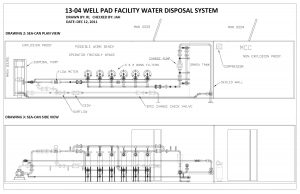

2. Produced Water Disposal Well System – 100 cu. m/day capacity

The 13-04 Well Pad Surface Facility includes nine oil wells and one water disposal well. The produced water treatment systems addresses injection pressure, oil and solids reduction, flow rate limits, and back pressure limits prior to injection down hole. The capital cost for this pad was approximately, $850,000 (includes pad upgrades, drilling, completions, surface facility additions, engineering, geology, and head office overhead)

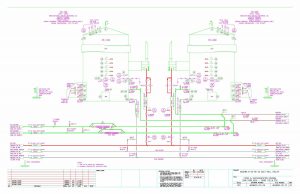

Plot Plan Drawing:

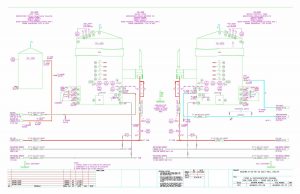

PFD Drawings:

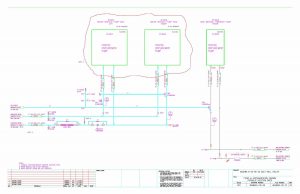

Equipment Layout Drawings:

Return to top

3. Single Well Test Equipment Setup

Single well production tests were performed from approximately, Nov 15 to Mar 15 (spring breakup) each year and subject to weather and ground conditions. The Muskwa area showed variability in pay depth, viscosity, oil saturation, water content, and production potential. Downhole pressure was approx. 2000 kPa. Based on HEI Groups experience with the Muskwa geological and geophysical information, as well as, information provided by expert colleagues, there is significant untapped potential in the Muskwa area – beyond where the existing well pads are. One neighbouring oil company has experienced great cold production success. There is also great opportunity for application of enhanced oil recovery technologies. HEI Group believes that once oil prices increase to US$70+ that this should trigger a new phase of exploration and development.

Plot Plan and PID Drawing:

Drawings to be added by April 2, 2018

Return to top

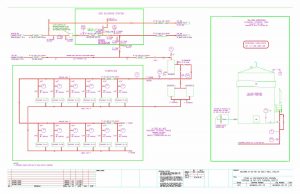

5. Other P&IDs

[Important Notes! – More drawings to be added in future]